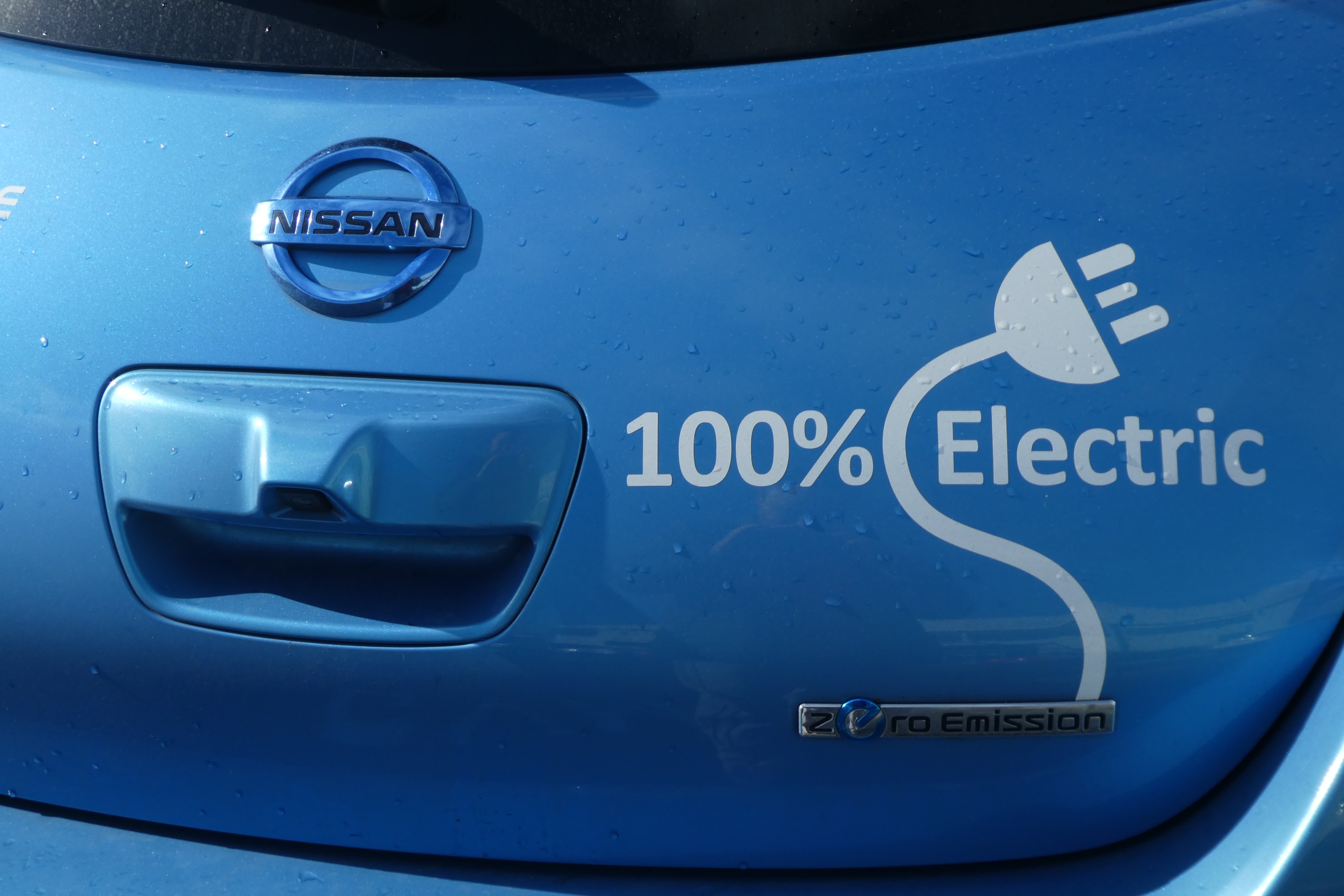

Are Electric Vehicles Going Mainstream?

There are over 3 million electric cars on the road worldwide, and their numbers are growing rapidly. The switch to electric vehicles (EVs) is surging in popularity, driven by environmental awareness, government subsidies, and better technology. In addition, EVs are cheaper to run and have lower maintenance costs. But just how sustainable are EVs to operate? From identifying green sources of power to recycling batteries, electric vehicles face sustainability issues. Addressing these problems quickly will improve their efficiencies and increase their adoption faster

There are over 3 million electric cars on the road worldwide, and their numbers are growing rapidly. The switch to electric vehicles (EVs) is surging in popularity, driven by environmental awareness, government subsidies, and better technology. In addition, EVs are cheaper to run and have lower maintenance costs. But just how sustainable are EVs to operate? From identifying green sources of power to recycling batteries, electric vehicles face sustainability issues. Addressing these problems quickly will improve their efficiencies and increase their adoption faster

Sources Of Power

Electric vehicles have fewer emission levels than conventional vehicles. However, the source used to power up an EV can only be sustainable if electricity is produced in an environmentally-friendly way. This means that energy must be acquired from clean sources, such as solar power, hydroelectricity and wind.

The 2019 Retail and Sustainability Survey showed that more than one two thirds of respondents consider sustainability when making a purchase. They are prepared to pay more for sustainable products. When it comes to personal vehicles, buyers are conscious of their carbon footprint, not only because of norms on emissions as dictated by law, but also because of economic costs. Comparing prices, fuel economy, and carbon footprint are some of the factors that may affect a consumer’s decision when choosing a ride. EVs that utilize green power, therefore, are more likely to be favored by consumers.

Recycling Batteries

Batteries are the lifeline of electric vehicles. Unfortunately, they have a limited life span. Once their performance begins to decline (characterized by more frequent plug-ins and fewer miles of driving, or after a certain age) it is no longer viable to keep them. They must be replaced every 7-10 years for smaller vehicles and every 3-4 years for bigger ones, such as buses and vans. By 2025, the global stockpile of batteries is going to reach 3.4 million, according to a Bloomberg report.

Recycling batteries is not an easy process. It involves smelting and direct recovery processes, amongst others. Due to the heavy metal content in batteries, utmost care is required in the separation process to avoid contamination of the soil and water. Moreover, there are not many plants that can recycle batteries because they cost a lot of money to build and maintain. Increasing the number of cost-effective and efficient plants in the future can help to ensure that batteries reaching the end of their life can be recycled properly.

Developing Cheaper Recycling Processes

It is critical as well to improve recycling methods to avoid reliance on facilities that are capital-intensive. For example, hyrdometallurgy processing or chemical leaching is practiced in China, and it is a less expensive and energy-intensive alternative in battery recycling. In addition, direct recycling methods are being developed by the US Department of Energy that will recover and reuse battery materials without exorbitant costs. The aim is to reuse all components of the battery.

At the University of Birmingham, researchers are focusing on economic efficiency of battery recycling through automation, developing robotic procedures for sorting, dismantling and recovery. Although the number of batteries that are at their end of life is still low, their numbers could skyrocket in the near future, making cheaper and more efficient methods of recycling an urgent task.

Given the rapid advances in technology for electric vehicles, they are expected to go mainstream faster than expected. However, in order to enhance their sustainability, efficient ways of storing energy, and finding cost-effective ways of recycling batteries are vital. Without these solutions, EVs might be just as problematic as traditional or combustion engine vehicles.

By Sally Writes.

Sorry, the comment form is closed at this time.